We offer a complete range of solutions from design to components assembly.

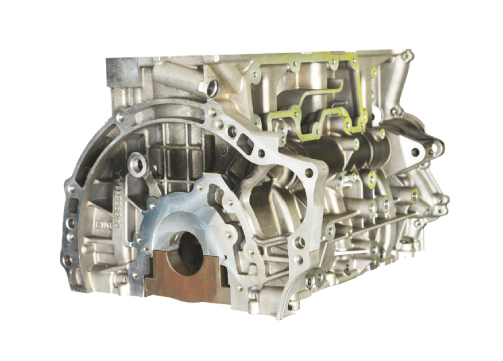

Our core business is complex mechanical components manufacturing.

Over the years the specialization in high-precision mechanical parts production, thanks to automated and high-tech processing centers, has allowed us to become among the most important partner of companies in the world in the automotive field.

Among our partners, we have: Fiat, Alfa Romeo, Audi-VW e Guado.

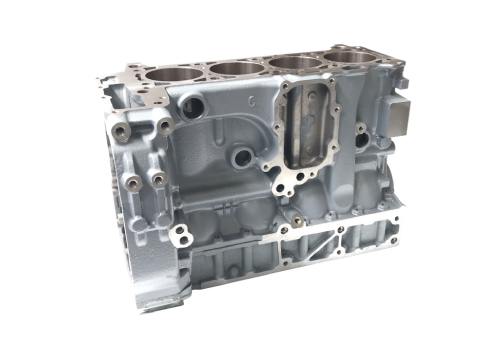

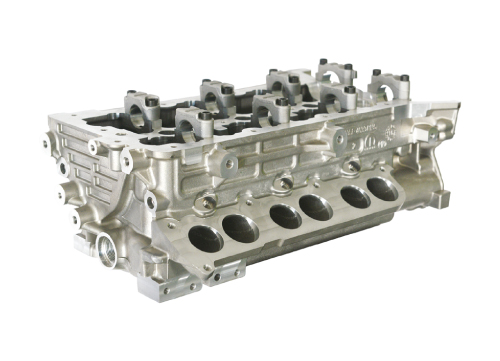

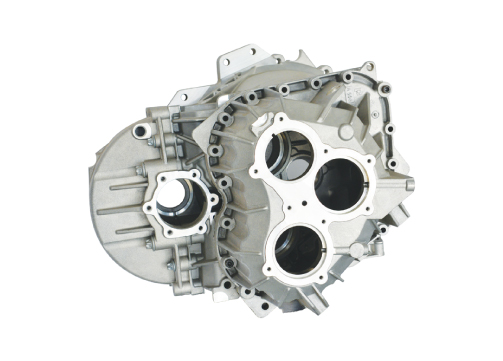

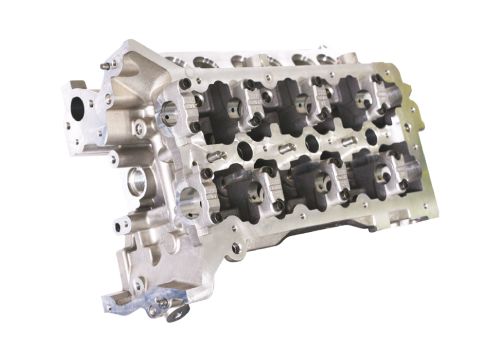

We are specialized in complex mechanical parts manufacturing of wide range, such as engine blocks, cylinder heads, exhaust manifolds, flywheels, cam shafts and drive shafts, oil sumps, injection pumps for Common-rail system and many others.

We like to combine our ability of developing innovative products to a flexibility which distinguishes all process steps: from design to testing, and are related to the serial production: logistic, packaging, protection.

We support our customer in all development product steps, trying to find the best solution that is successfully and quickly.

Our added value is enclosed in the ability of providing quality products at the right price.

That’s why this ability allows us to increase turnover and market share every year.

In order to meets the needs of our customers, within our plants we organized the production process in working stations. This process allows us to adapt production from time to time and to optimize the processing special materials (range of aluminium, iron and steel), in volumes ranging from few tens parts a month to thousands a day, and weights ranging from few grams to hundreds of kilograms.

All this ensures that all parts of processing comply perfectly with the specifications supplied by the developer, and is made possible only by a solid planning related to an accurate organization.

Steel, volumes 70k units/year supplied ended of processing, washed, tested and with assembled components. Ready for assembly on the engine.

Applications

Maserati Ghibli, Maserati Levante, Maserati Quattroporte, Jeep Gran Cheeroke, Dodge Ram Wrangler Pick up.

Grey iron, volumes 55k units/year, supplied ended of processing, included sanding reeds with assembly of components.

Applications

Tractors New Hollad Cnh

Applications

Motorbike Mv Agusta

Steel, volumes 6k units/year supplied ended of processing, nickeled varnished and coupled upper/lower.

Steel, volumes 35k units/year supplied ended of processing, washed, tested.

Steel, volumes 75k units/year supplied ended of processing, washed, tested and with assembled components. Ready for assembly on the engine.

Steel, volumes 55k units/year supplied, of processing, supercubed, washed and by sealing test.

Grey iron, volumes 25k units/year supplied ended of processing, included sanding reeds with assembly of components.